Discover Who We Are

Goshan Machinery delivers high-performance wear-resistant components and crusher parts through advanced casting technologies and ISO 9001:2015-certified processes. We empower industries to cut costs, extend equipment life, and boost efficiency.

Source Foundry Price

ISO 9001:2015 certificated

Quick Delivery in 15 Days

Exceptional After-Sales Care

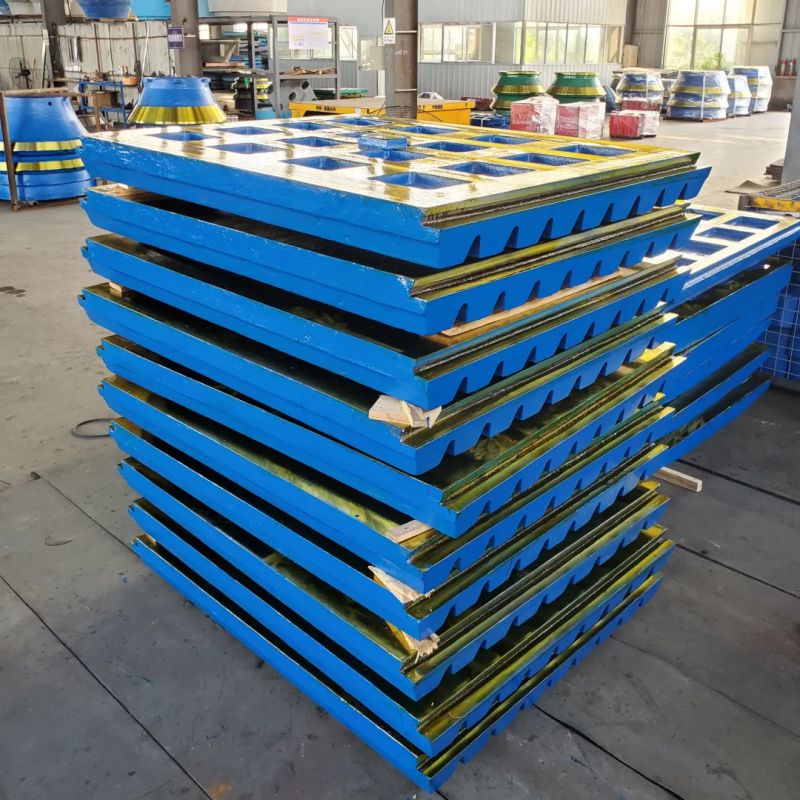

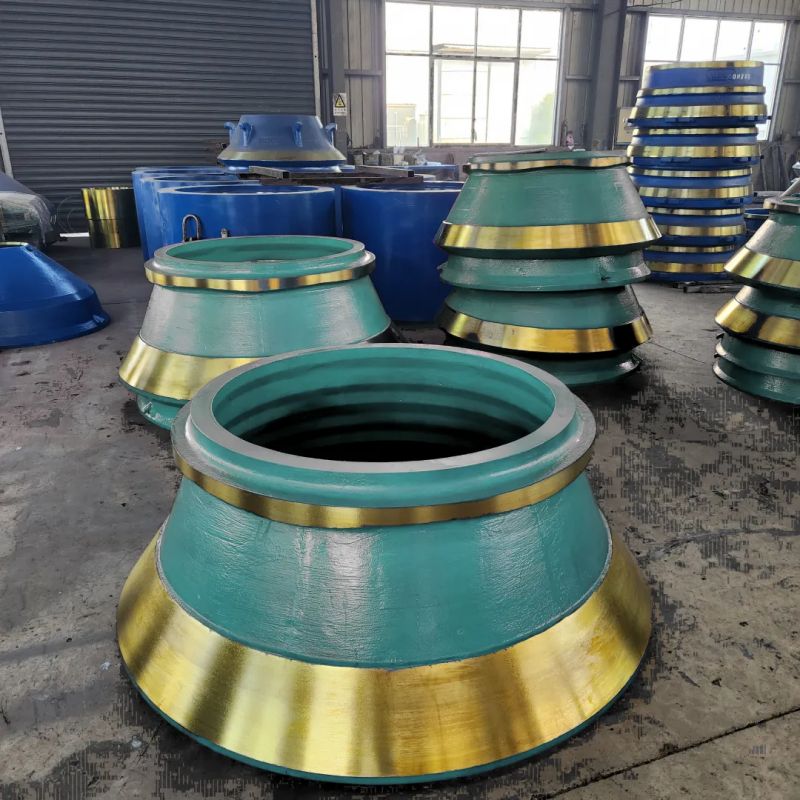

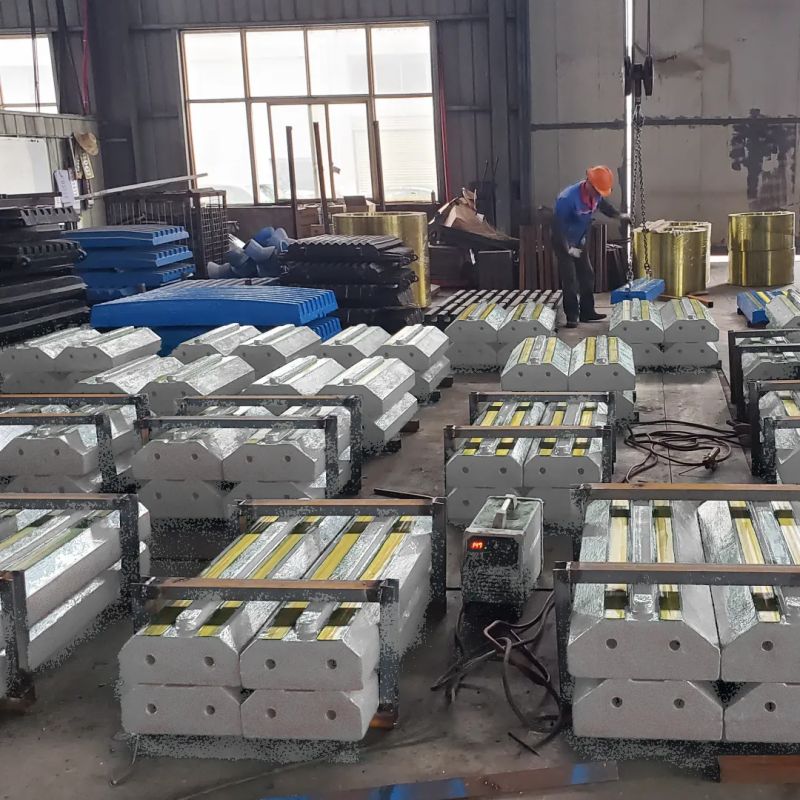

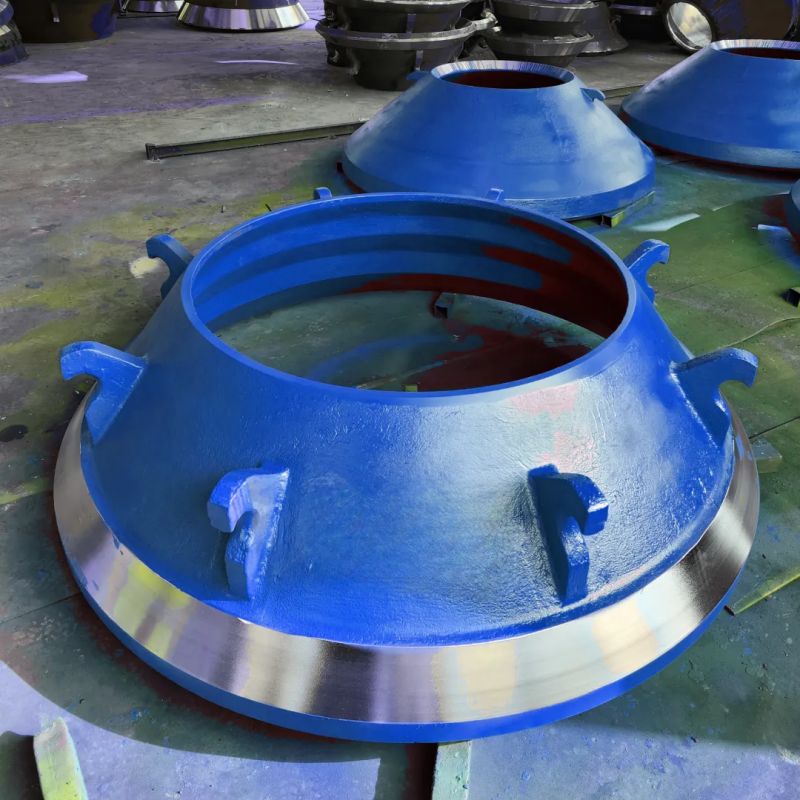

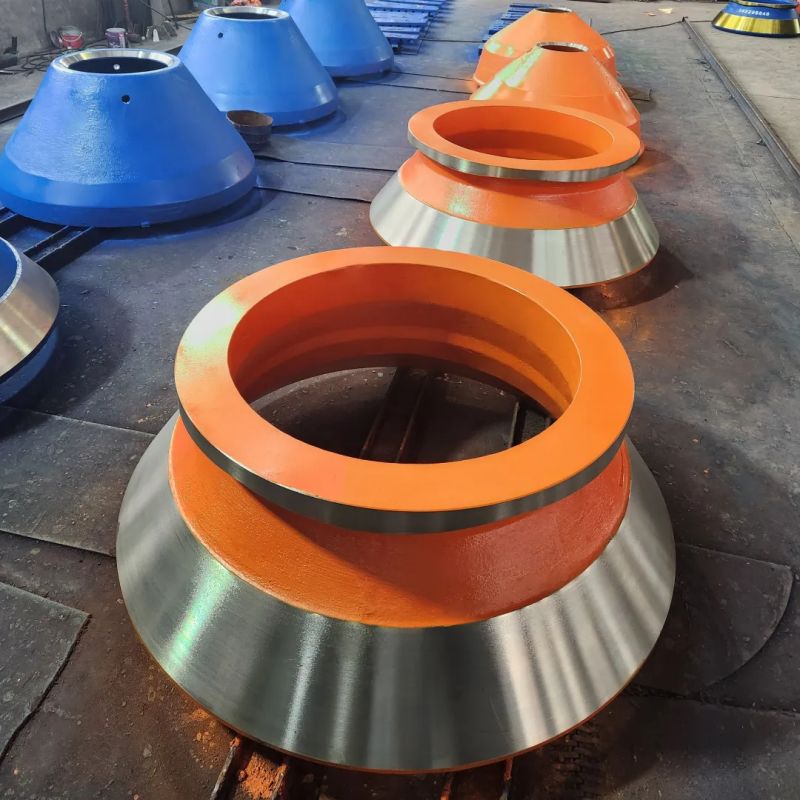

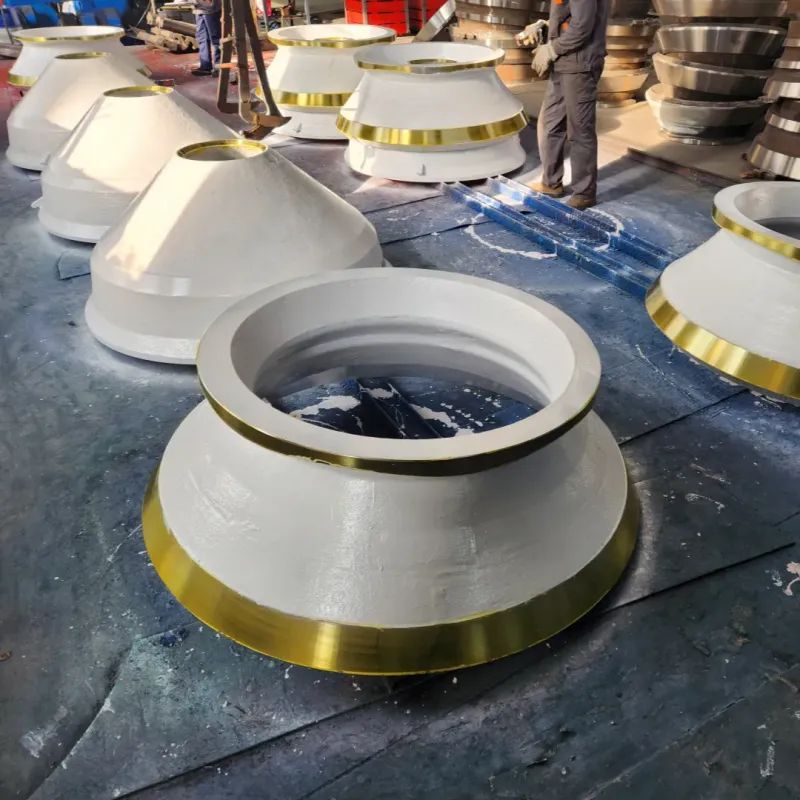

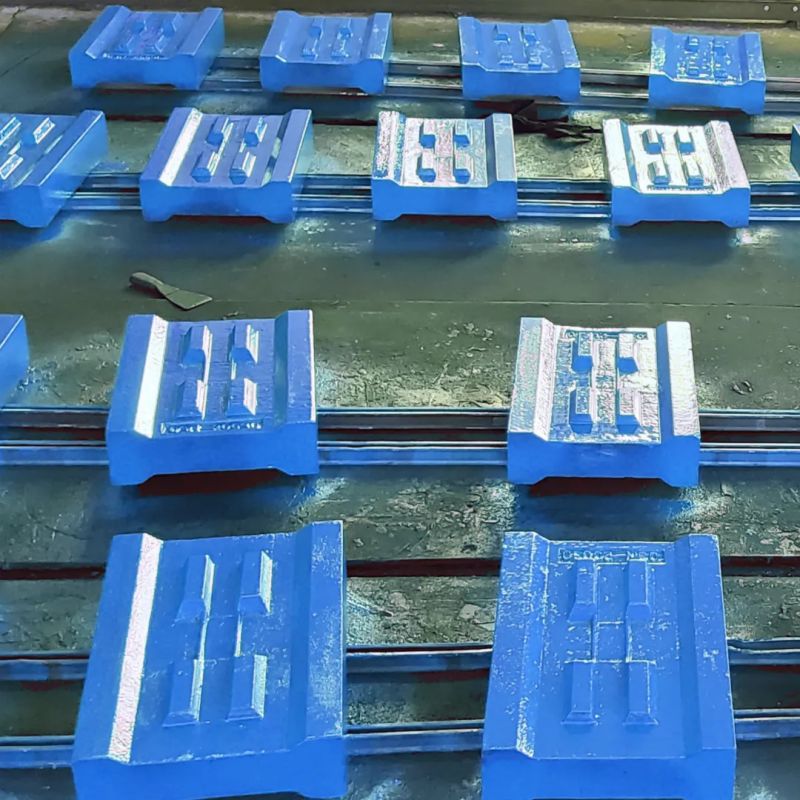

Crusher Wear Parts from Our Foundry

Jaw Plates Concave Blow Bar&Impact Plate

“All manufacturer names, logos, symbols, etc. are used for reference purposes only and does not imply that any part listed is a direct product of these manufacturers.”

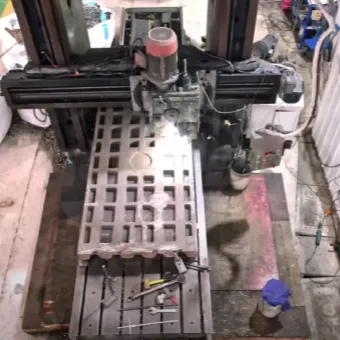

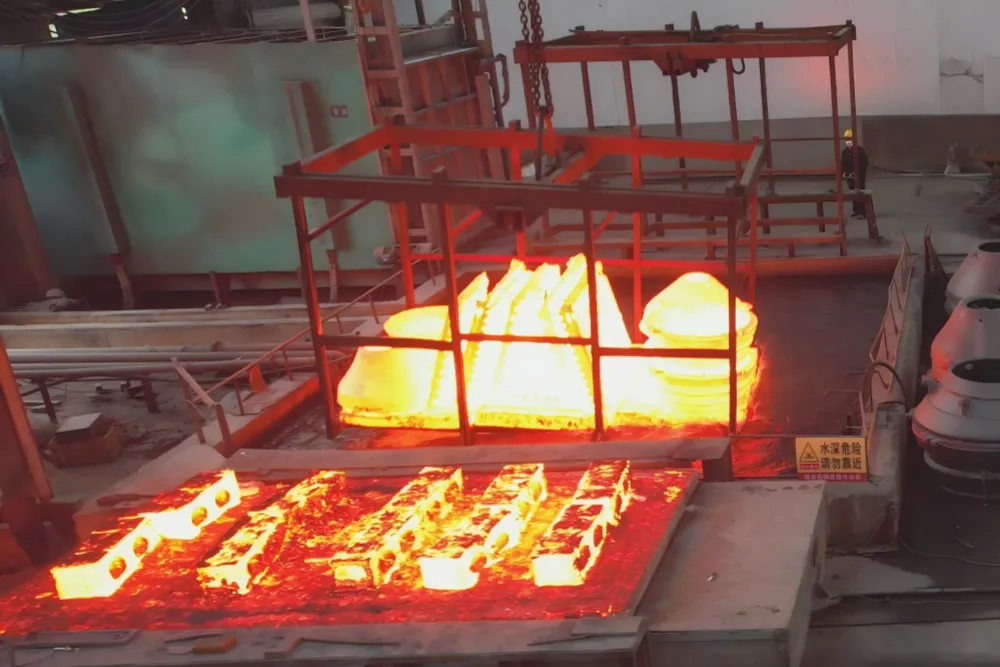

ISO9001:2015 Certified Foundry Foundry VR Tour

Goshan Machinery rigorously follows ISO9001:2015 standards across every production phase. Our precision casting, systematic quality controls, and end-to-end testing guarantee durable wear parts that reduce downtime and boost your productivity.

Complete Inspection ensures Quality

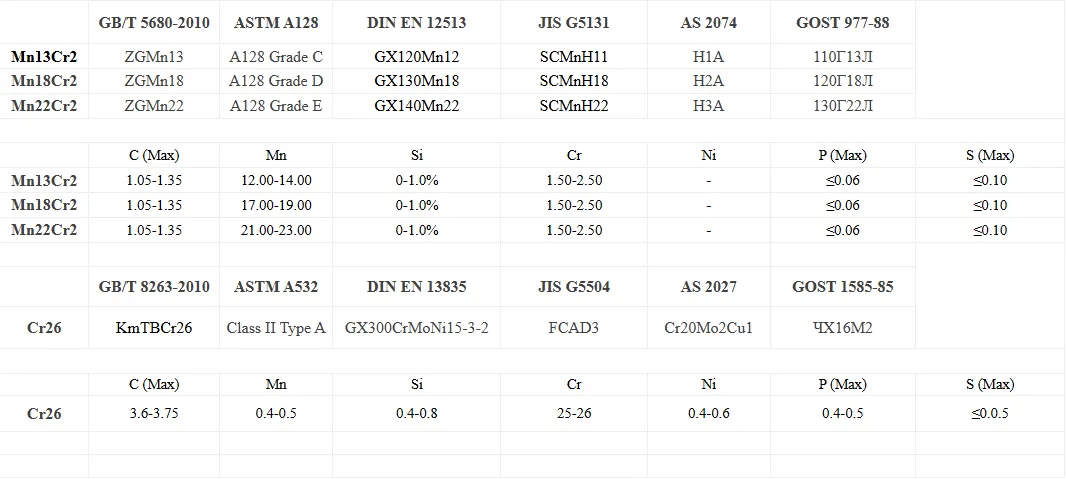

To ensure the chemical composition of our products meets the required material standards, we conduct thorough testing immediately after each casting process. This allows us to generate accurate Chemical Composition Reports, confirming that every wear part adheres to the specified material properties. By maintaining this rigorous quality control, we guarantee that our products deliver the performance and durability your operations demand.

Every product undergoes 100% heat treatment to ensure superior quality. This process enhances hardness for improved wear resistance and longer service life, increases strength, improves toughness, optimizes machinability, and eliminates internal stresses, delivering reliable performance in demanding conditions.

Every product undergoes rigorous dimensional inspection to ensure it matches the design specifications and fits perfectly into your machinery, guaranteeing seamless installation and optimal performance.

Hardness is a critical measure of a wear part’s durability. Every product we manufacture undergoes rigorous hardness testing to ensure it meets the highest standards, delivering long-lasting performance in even the most demanding conditions.

This is a crucial step in our quality control process. It helps detect surface and subsurface defects, such as cracks, ensuring every product is free from flaws and ready for reliable, long-term use.

Here is Goshan Machinery

Reliable Crusher Wear Parts Solutions

Specializing in custom crusher wear parts, we use advanced technology to create durable, high-performance solutions tailored to your equipment and needs.

Timely Delivery Guaranteed

Our skilled team works tirelessly to ensure your orders are delivered on time, every time, with outstanding performance when you get your order.

Logistical Benefits

Located close to both Ningbo Port and Shanghai Port, we offer significant logistical advantages in the export of mining equipment and shipment of goods is internationally.

Certified Quality Assurance

We adhere to strict quality control measures and are fully compliant with international standards, guaranteeing both product quality and reliability.

Become our next Valued Partner

Mandla Ndlovu

Quarry Owner

“Their wear parts have not only reduced our maintenance costs but also improved our overall efficiency. They’ve been a trusted partner in solving our operational challenges.”

Diego Ramirez

Importer&Distributor

“Their products are consistently high-quality and offer great value, which has helped us win over more clients. The technical support from their team is also top-notch and always on time.”

Thabo Khan

Quarry Owner

“Thanks to Goshan Machinery, our operations run more smoothly than ever. Their wear parts are reliable, and their service is top-notch.”

Mei Lau

Operations Director

“Goshan Machinery has transformed our operations with their high-quality wear parts. We no longer face frequent breakdowns, and our productivity has improved dramatically.”

William Clark

Quarry Owner

“Their products have solved our biggest challenge—frequent wear part replacements. Now, our operations run smoothly, and our costs have decreased significantly..”

Quality First, Support Your Success!

We focus on sustainably offering high-quality crusher wear parts and dependable services globally, simplifying success with one-stop solutions for our customers.

Contact With Goshan MachineryGet in Touch With Us

FAQ

Q: What are your product advantages?

A: Three key strengths:

1. Material: The material composition fully meets the standards or exceeds the standards, and the product quality is stable and reliable

2. Technology: The engineering team is strong, and the technical workers are experienced, with more than 10 years of industry experience.

3. Service: Sales staff are proficient in international trade, online 24 hours a day, 365 days a year, and professional services make customers worry-free.

Q: What’s your production lead time?

A:The fastest15 days for standard patterns; 45 days for new designs. Confirmed upon formal order.

Q: What products do you offer?

A: Specialized in crusher wear spare parts (jaw plates, concaves, mantles, etc.), suitable major brands. Custom solutions available.

Q: How do you handle quality issues?

A: Rigorous pre-shipment inspection + 3-step resolution:

1.Photo analysis of failed parts;

2.Free replacement if quality-related;

3.Technical guidance for operational improvement

- No.69 Yifu Road, Zhuangshi Street, Zhenhai District, Ningbo City, China

- info@goshanmachinery.com

- No.922 Gangcheng Road, Yushui District, Xinyu City, China

- +86 135 0668 2876